Free delivery on orders over €175?

Offset or digital printing on orders from 100 pieces

Wide selection, low prices

Sealers

What is a sealer?

A sealer or a seal machine is used to make plastic bags or (stand-up) pouches airtight. By heating and compressing the packages, the contents are protected from air, moisture and other external factors. Here is a brief explanation of the process:1. Preparing the packaging: Place the product you want to seal in a plastic bag, stand-up pouch or foil packaging. For a good seal the opening of the pouch or bag must be clean and free of dirt or moisture.

2. Placing in the sealer: Place the open ends of the pouch, the sealing bar, into the sealer.

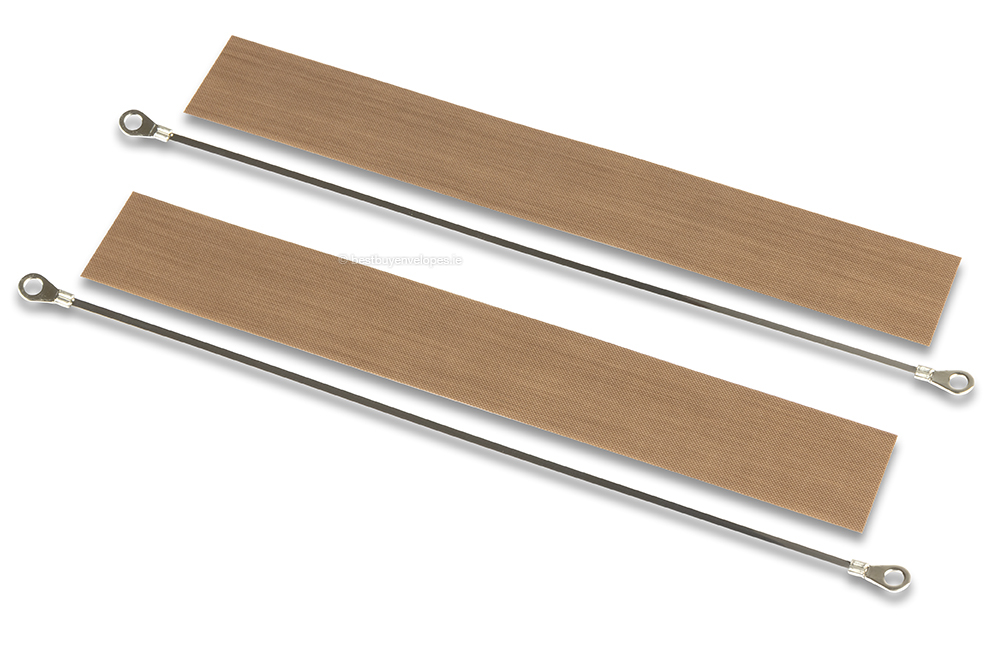

3. Heating and sealing: The sealer has a heating element to melt the plastic at the open ends of the pouch. Impulse sealers use a short, powerful electric pulse. Constant heat sealers use a heating element that provides continuous heat. At the same time, the edges of the pouch or bag are squeezed together, bonding the molten plastic layers and creating an airtight seal.

4. Cooling and hardening: After the pouch is sealed, the plastic quickly cools and hardens to ensure a tight seal.

5. Checks and storage: Check the seal to make sure that it is completely airtight and there is no chance of leakage. The sealed package is now ready for storage, transport or use.

Benefits of sealing products

Sealing increases the quality, shelf life and safety of products. Sealing has important selling points:• Extended shelf life. Airtight seals slow the growth of bacteria and moulds. This is especially beneficial for foods. It will keep food products fresh for a longer time.

• Protection against moisture and dust. Sealed products are protected from environmental factors such as moisture, dust and dirt. This is important for both food products and non-food products such as electronics and medical devices.

• Preserving flavour and quality. Sealing foods helps preserve flavour, texture and nutritional value by reducing oxidation and preventing dehydration.

• Less food waste. Food will keep longer. Less food is thrown away which is both economically and environmentally beneficial.

Types of sealers

Our sealers can be divided into two categories:

Impulse sealers:

These sealers use a short, powerful heat pulse to make the seal. Bestbuyenvelopes offers two types of impulse sealers; a seal length of 200 mm or a seal length of 300 mm.

Constant heat sealers:

These sealers have a continuously heated element for sealing thicker materials. Bestbuyenvelopes offers three different types of heat sealers:• Sealer Type 150C: This heat sealer is easy to operate and particularly suitable for sealing small quantities of (stand-up) pouches.

• Sealer Type 420CT: These handheld sealing tongs are extra convenient. The 4.5-meter power cord gives you the flexibility to walk around and seal your products on the spot.

• Heat sealer Type 302LM: a smart compact semi-automatic tabletop heat sealer with foot operation that leaves both hands free for packaging.

Which is the best sealer for you

Which type of sealer is best for you to use with our products?

Impulse sealers:

Materials: Polyethylene and polypropyleneProducts: Block bottom pouches transparent

Stand-up pouches transparent

Plastic transparent pouches

Shipping bags COEX

Grip bags

Foil envelopes

Heatsealers:

Materials: Polypropylene, Cellophane, Paper and Aluminum laminateProducts: Our range of stand-up pouches

Block bottom pouches coloured

Block bottom paper bags with window